Nickel plating is a technique of electroplating a thin layer onto a metal object. This process can add brightness and appeal to the product. Nickel plating works by creating a corrosion-resistant layer that will prevent the base metal from rusting. The nickel layer can be decorative or used to firm up worn areas.

This process can make mechanical parts and tools more durable and performance-enhancing, and it can allow you to solder to difficult metals. Decorative finishes can be achieved, from a chrome-type shine to a brushed stainless steel sheen and even a metallic black. Black nickel plating is often used in aerospace applications. If thicker plating is applied, the object can turn magnetic.

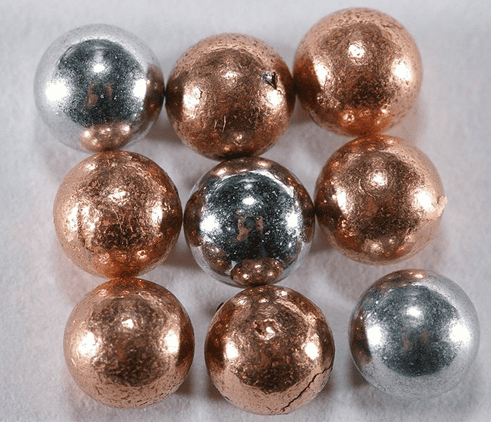

Nickel-plated coatings can be decorative or functional

One of the main aims of nickel plating is to amend the properties of the surfaces requiring plating, such as the conductivity, or to improve their durability, appearance and performance. Electroplated nickel is often used in consumer goods and is becoming a process that is used more and more for a variety of manufacturing applications. Electro nickel plating involves an electrical current coating a material, often made from metal, with a thin nickel. Other metals used for electroplating include stainless steel, zinc, copper and platinum.

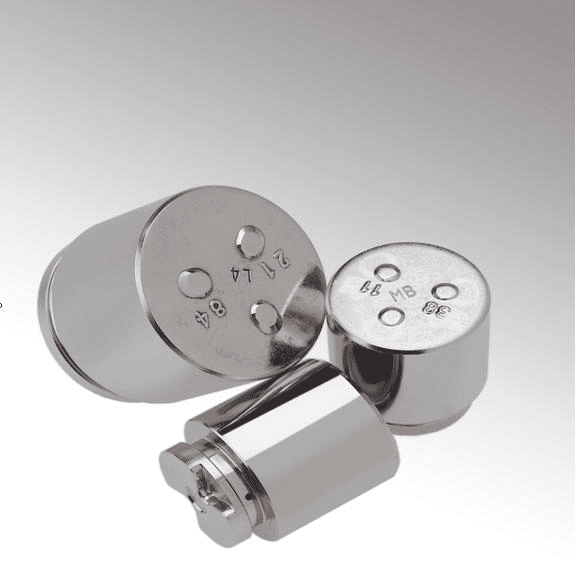

Car manufacturers use plating to prevent wear and tear

A range of surface treatments is available for customers who require bespoke solutions. Industry-standard coatings ensure that the surface treatments are of an excellent calibre. Car manufacturers carry out this process to ensure parts such as fuel injectors, pistons and cylinders are protected from wear and tear and corrosion. Valves and engine shafts in the aerospace industry will also benefit from the coating.

The oil and gas industry applies electroless nickel plating to equipment that is required to withstand harsh conditions underground. This is an essential part of pumps and pipe fittings. Nickel plating can also be found in electronic products; for example, consumers may notice the plating in hard drives and printed circuit boards.

If corrosion is a huge concern in the industry, electroless nickel should solve the problem and should be the first choice of plating material. The smoothness of the plating ensures no moisture will penetrate, which will add an extra layer of protection to the items. This will help them to perform better and last for a longer period.