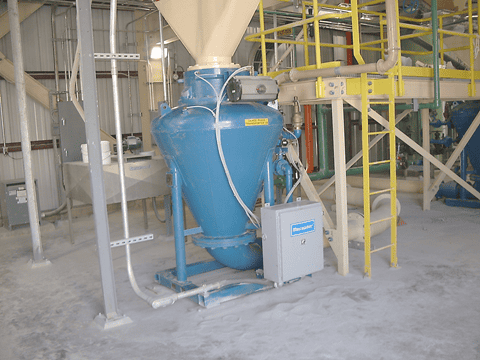

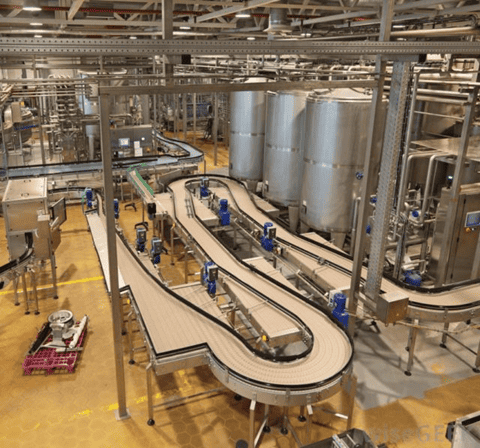

These machines are responsible for moving items, from parts to finished products, through various production stages in a factory or plant. As a result, the conveyor belt has become one of the most important tools in modern manufacturing. The process of manufacturing is more efficient when these belts can move items at a steady speed and maintain their shape and size over long distances. For more information on Pneumatic conveying systems, visit https://www.aptech.uk.com/pneumatic-conveying-systems/

The conveyor belt, as the name implies, moves things on a belt, which is made up of pulleys that are attached to a fixed gear. Each belt can be equipped with several wheels in order to reduce wear and tear, and to reduce the amount of materials that need to be transported. This method of transportation eliminates waste, as there is no need to load products into a truck or trailer and then unload them to a loading dock to be hauled away. Instead, the product is simply loaded onto the belt and moved along it until it reaches the assembly or finishing point, where it is ready to be packaged and shipped off.

The conveyor belt was used extensively in factories. It has now been adapted to the industrial arena as well. There are several types of conveyors that can be used in manufacturing, but conveyors can be categorized according to what their purpose is. A trolley conveyor is one type of conveyor that is used for moving items from one area of the plant to another. These conveyors move in a linear fashion, moving products along tracks. The next classification is a drum conveyor, which moves objects along an axis. These conveyors are also used for transporting items, though they tend to be larger than trolleys.